Choose the right material to make challenge coin

Choose a suitable material to make a challenge coin.

- Brass

- Iron

- Zinc

- Gold

- Silver

- Bronze

- Copper

- Nickel

Custom challenge coin process

The custom challenge coins process consists of 9 steps. Follow these steps to make your challenge coin.

1. Production of Mold

Manufacturing of custom challenge coins mold starts the image placement in the software.

Next, the CNC machine reads the blueprint to mill the inverse coin’s design image into a steel die on both sides.

Manufacturers ensure the challenge coin design accuracy. Then, they temper it to verify the mold’s strength.

Molds stamp the coin. Proper coin placement in the mold prints the image without any discrepancy.

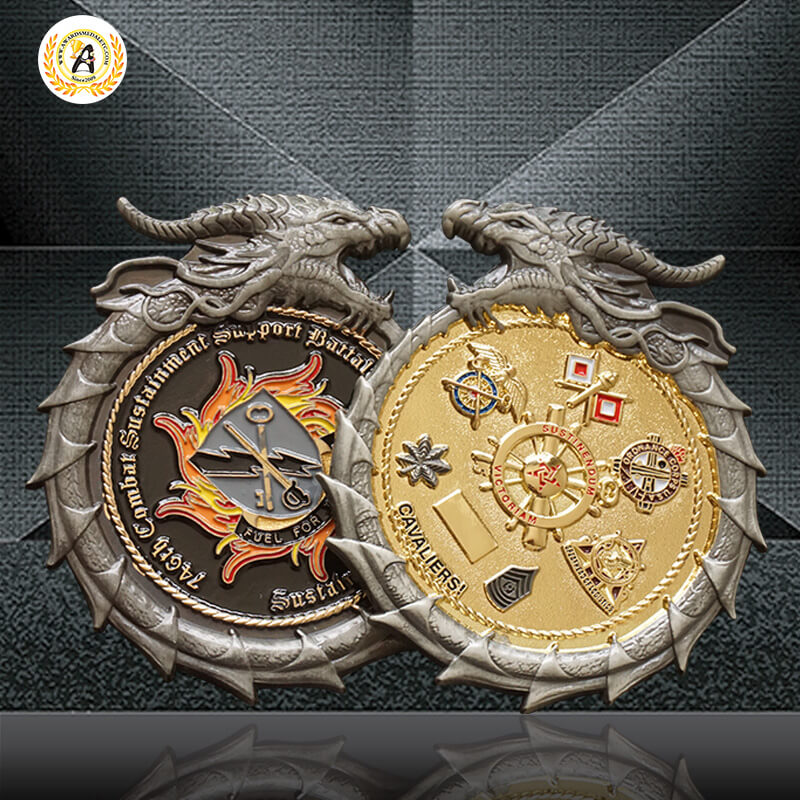

2. Die striking

Now, it undergoes stamping by printing dies on a blank coin. Not only image printing, it also adds raised elements detailing for more depth and feel. The process repeats to achieve the desired design and detailing.

3. Edging option

Edging in custom challenge coins provides more uniqueness. You can customize edge options like diamond cut, oblique line, spur cut, etc.

4. Deburring and polishing

The custom challenge coin edge remains sharp after the die-striking process. Deburring takes place to remove the sharp edges,

Next is the polishing process. A polished challenge coin will be anti-corrosive and prevent tarnishing. Buffing wheels and a compound polishes the coin. But, the type of compound used varies between different metals.

A diamond compound polishes white metal and stainless steel. At the same time, a rouge compound polishes brass and yellow metals.

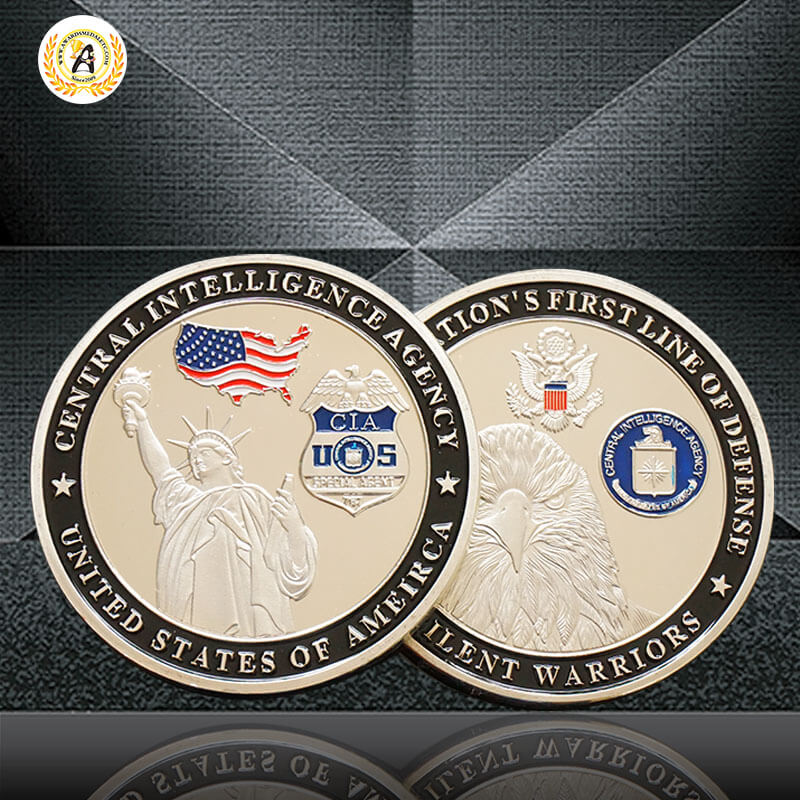

5. Coin plating

Coin plating is the most integral part of the coin manufacturing process. It delivers the coins with cheap material and the same feel and appearance.

This process uses iron and zinc as the coin’s base material. Later, a thin layer of gold, silver, copper, etc., was applied to give the desired appearance.

6. Metal texturing

It is an extra feature providing texture beneath the challenge coins’ custom design. Coins are commonly textured or rough surfaces, depending on the choice.

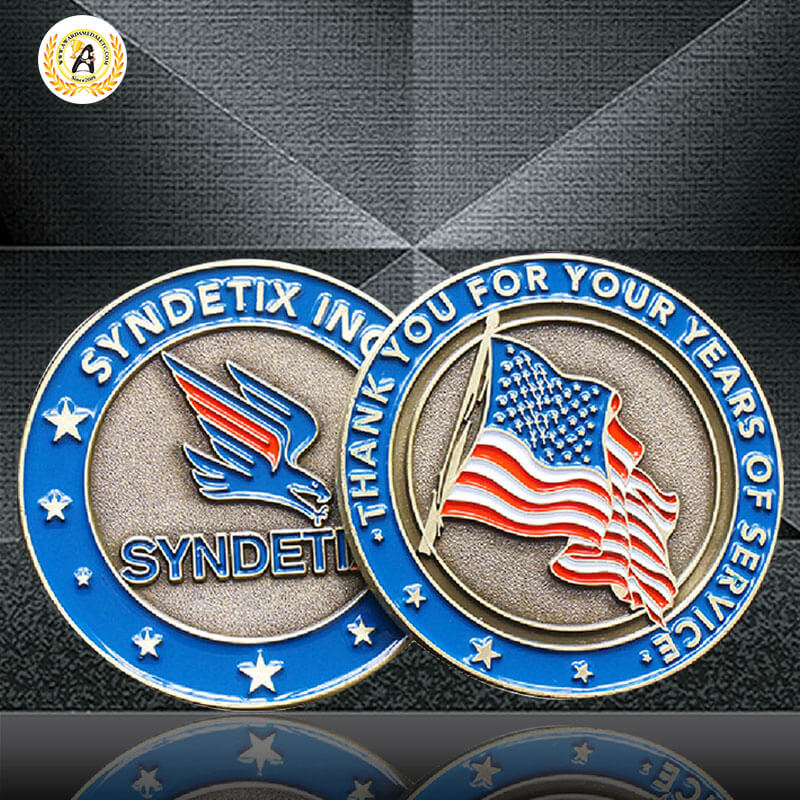

7. Coin Coloring

Rather than a coin with natural color, a colored coin looks more stylish and personalized. Here are three steps for coin coloring:

Hard enamel: Used to apply paint on the coin’s surface

Soft enamel: Applies color to the coin’s recessed areas

Pad printing: Applies ink to the coin to make a permanent color finish.

8. Laser engraving

Laser engraving incorporates a minute design over the coin’s base and edges. With laser engraving, text on the surface or the edges enhances the coin’s look. Laser engraving on the sides makes custom challenge coins more appealing.

9. Finishing process

Design checks, look, feel, and durability finalize the custom challenge.

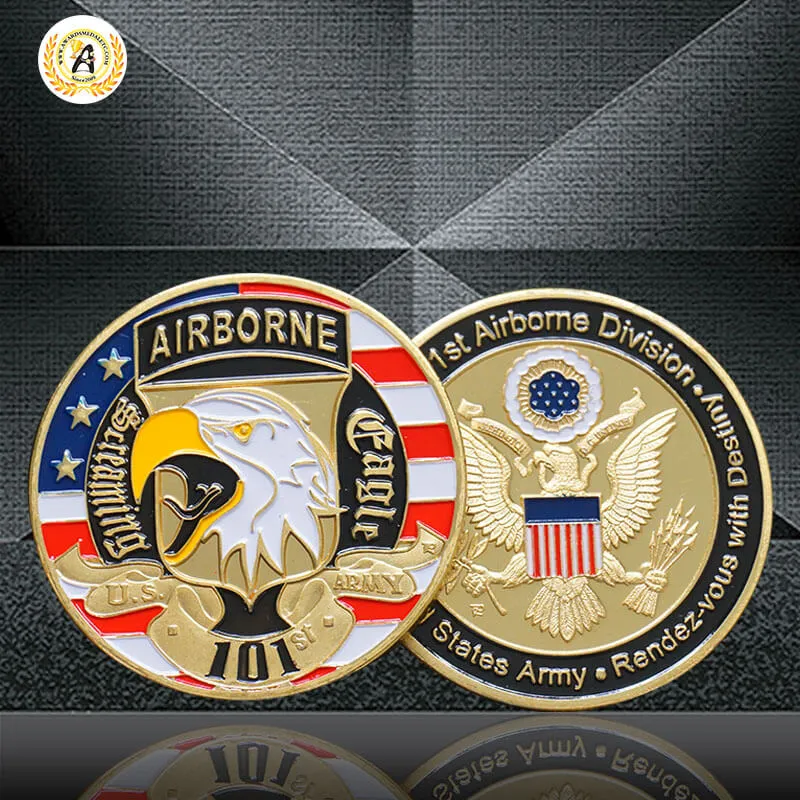

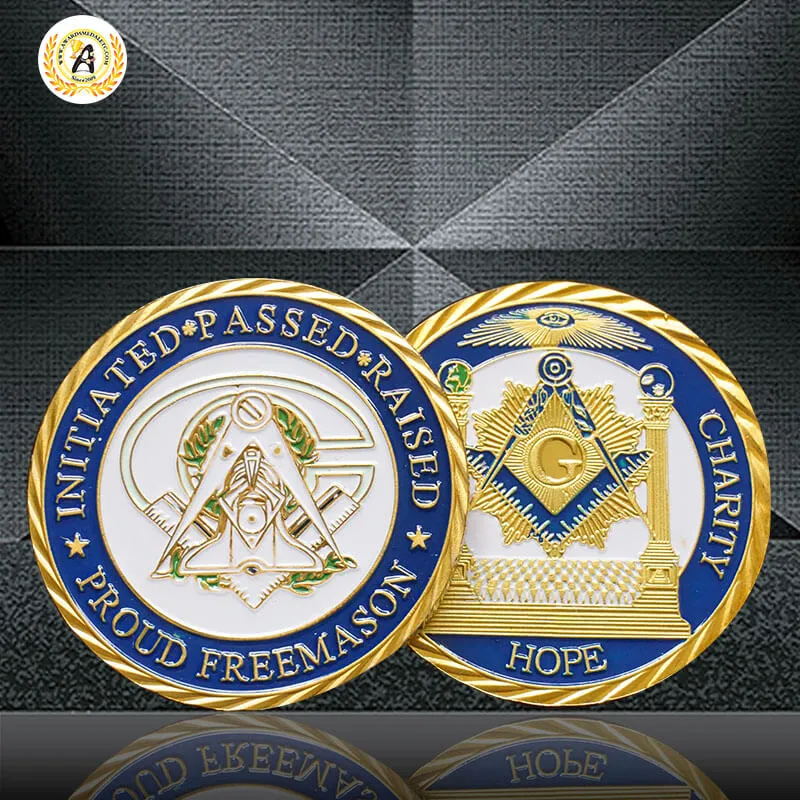

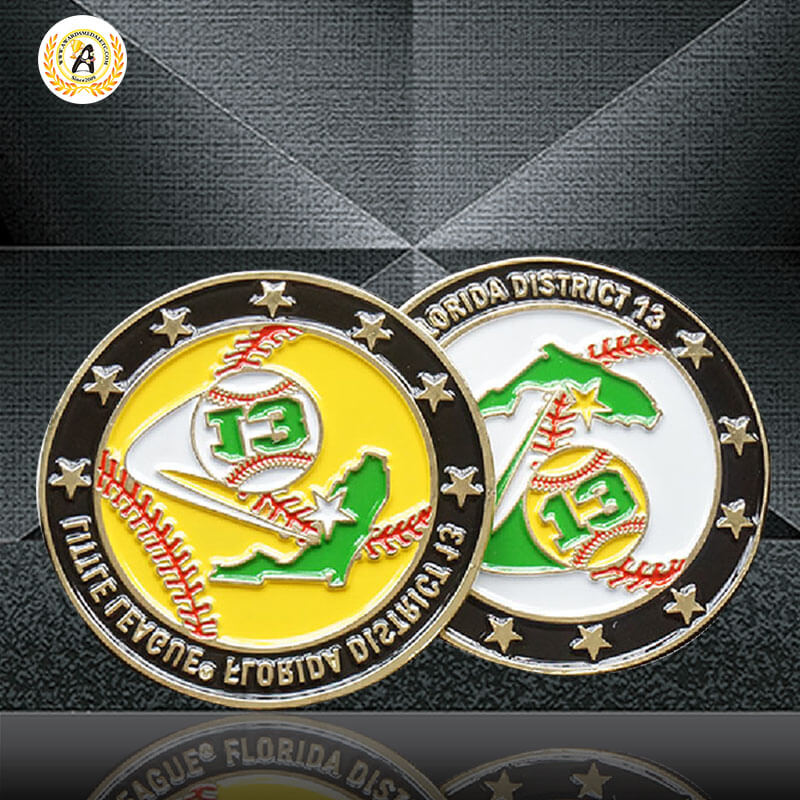

Custom challenge coins: creativity options

Here are the four customization options available to develop unique custom challenge coins.

1.Edge engraving

- Standard flat edge

- Rope edge

- Spur ledge

- Chain edge

2. Surface texture

- Smooth: provides a smooth coin surface and is polished to a high shine.

- Sandblasted: provides a textured or matte finish with a frosty or grainy appearance.

- Antique: Provides an aged or weathered look.

- Diamond Cut Edge: Provides grooves to the customs challenge coins’ perimeter.

- Soft Enamel: Provides a raised texture

- Epoxy Coating: Provides smooth glossy coating to protect the design elements underneath.

- 3D Sculpted Texture: Provides raised portions to the coin, creating depth in design.

3. Pattern colors

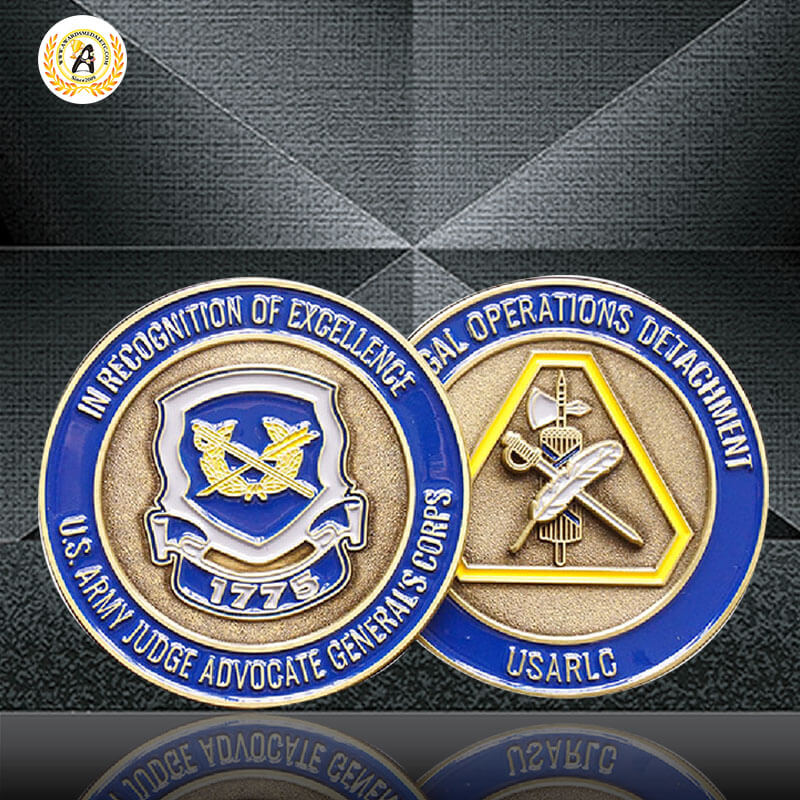

- Antique plating: Challenge coins have less reflection. It also provides natural shadows and hues in the raised and recessed areas.

- High polish plating: High polish plating provides legible elements and maintains the feel.

- Dual plating: Provides a combination option of two or more plating. This mix-and-match balance results in striking color that does not rely on only color fill.

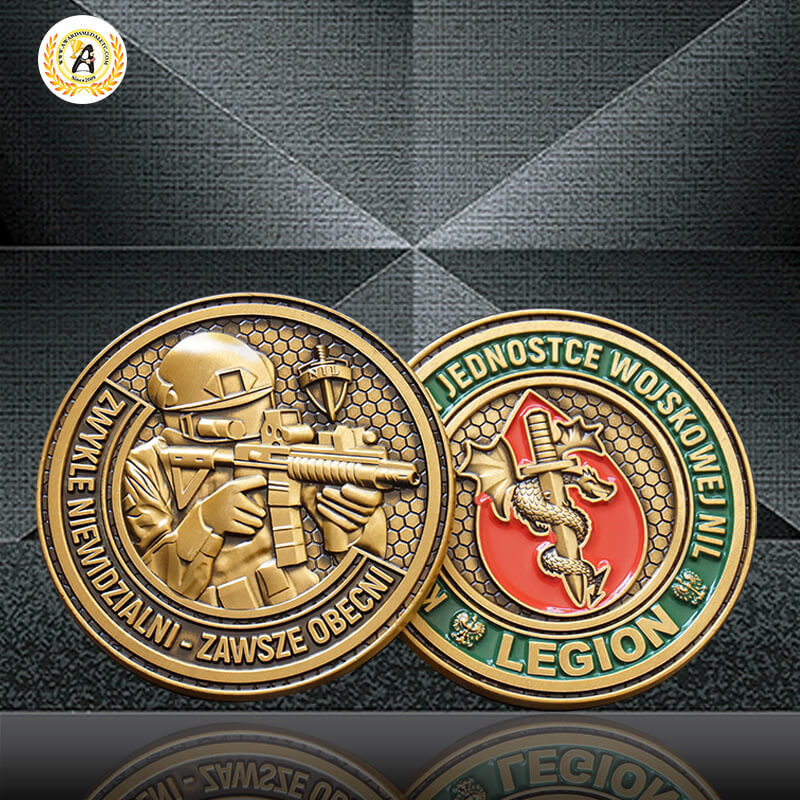

4. 3D Sculpted Detail

This includes 3-dimensional details such as Vehicles, People, Mountains, etc.

5. Value and appeal for personalized customization

Custom challenge coins designed for an organization consist of particular motives and purposes. Custom challenge coins may depict an event or a story about the bearer’s untiring efforts.

Quality checks on custom challenge coins

Several quality checks apply after custom challenge coins production to ensure the standards.

Delivery method and timeline

Custom challenge coins are offered in different ways and follow some rules. Types of custom challenge coins and occasions affect the rules. Here are some popular ways to deliver challenge coins:

Method

- Handshake: The giver shakes hands with the recipient and passes it from one to another hand

- Presentation: The giver delivers a speech before handing it over.

- Coin Check: Custom challenge coins are also “challenged” at any time by any group member. To start a coin check, a member slams their coin on a table to declare a challenge. Everyone else present must then produce their coin. If someone fails to pay, they might buy a round of drinks or perform some other agreed-upon task.

- Mail or Package: Delivered via mail or delivered in a package.

- Custom challenge coins ceremony: Challenge coin offerings take place in ceremonies.

Timelines

Factors like quality, design complexity, etc., affect the delivery timeline. Here is a rough idea of the delivery timeline of challenge coins:

- Design and Approval:1-2 weeks

- Production:2-4 weeks

- Shipping:1-2 week.

- Total timeline:4-8 weeks

From coin design to final delivery, there are several steps to creating a challenging coin. As a coin goes through all the steps, you get a visually appealing, high-quality challenge coin.

Custom challenge coins hold great importance in recognition and commemoration. They foster a sense of pride, remind shared experiences, and represent motivation. They speak of unbreakable bonds and show appreciation.

What’s next?

Are you ready to own your custom challenge coin today? Contact us, and let us help you story-tell your vision via an exclusive and unique custom challenge coin.